Description of the device

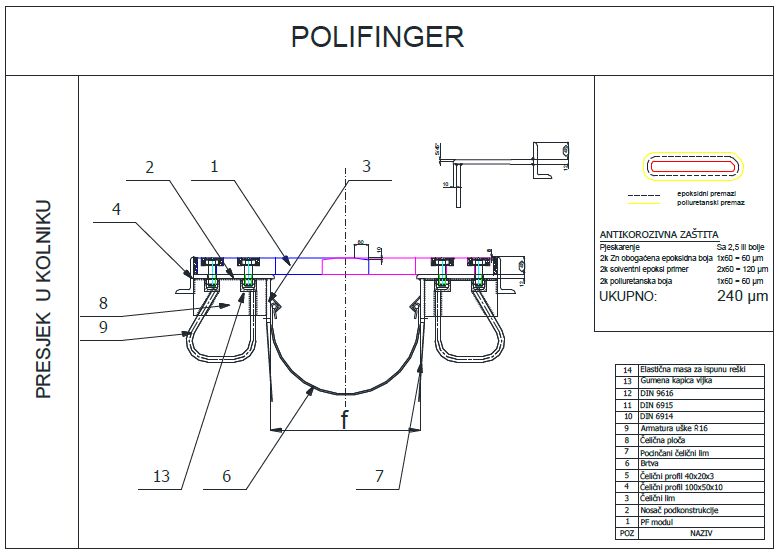

Finger expansion joints of the bridge consist of a series of modules comb , made by casting or machining of steel on steel plates (not welded parts ) , the size and weight of modules are optimized to be easy to manipulate and transport .

Finger expansion joints of the bridge consist of a series of modules comb , made by casting or machining of steel on steel plates (not welded parts ) , the size and weight of modules are optimized to be easy to manipulate and transport .

The advantage of these modules is the interchangeability of the site in case of damage . Steel modules are fastened with screws for high-quality steel substructure , which is anchored in the construction of abutments or superstructure of the bridge . Between the steel comb modules and steel substructure , mounts reinforced EPDM rubber gasket , reinforced fabric, which provides waterproofing expansion joints .

Permanent factory control all production processes and the use of high quality materials , ensuring high quality POLIFINGER expansion joints .

Corrosion protection ( two-part epoxy paint obogaćna zinc + component epoxy primer + two-component polyurethane paint ) provides high-quality and long-term corrosion resistance , in accordance with the class C5 according to EN 12944-5:2008 .

The concept design

The main purpose of expansion joints is to allow smooth shifts forehead superstructure and bridge the gap between the buildings of the forehead and the abutment, so that the traffic is smooth.

Expansion joints by filling structural holes in the construction of the bridge must meet:

- safe load transfer

- solid structure components

- retail spending

- constant adaptation versus deformation

- waterproofing

- use of materials resistant to aging, corrosion and abrasion

- durability and easy maintenance

Elements of expansion joints

| ELEMENT The supporting elements STEEL FINGER "PF" MODULE SUBSTRUCTURE Connection PDF modules and structures BOLTS NUT sealing means RUBBER GASKETS Anchoring ANCHORING IN THE ROADWAY FITTING ANCHORING PROTECTION OF BOLT |

DESCRIPTION molded or cut module of steel S355J2 + N hot rolled profiles and satin steel S235JR or better DIN 6914 TZV HV 10.9 lubricated with silicone grease + washers DIN 6916 TZV HV 10.9 DIN 6915 TZV HV 10.9 Reinforced EPDM rubber, high resistance to tearing, aging, salt water, oil; reinforced with two layers of textile satin steel S235JR or better reinforcing steel B500B or drawn steel S235JR rubber cap screws NR 60 Shore |

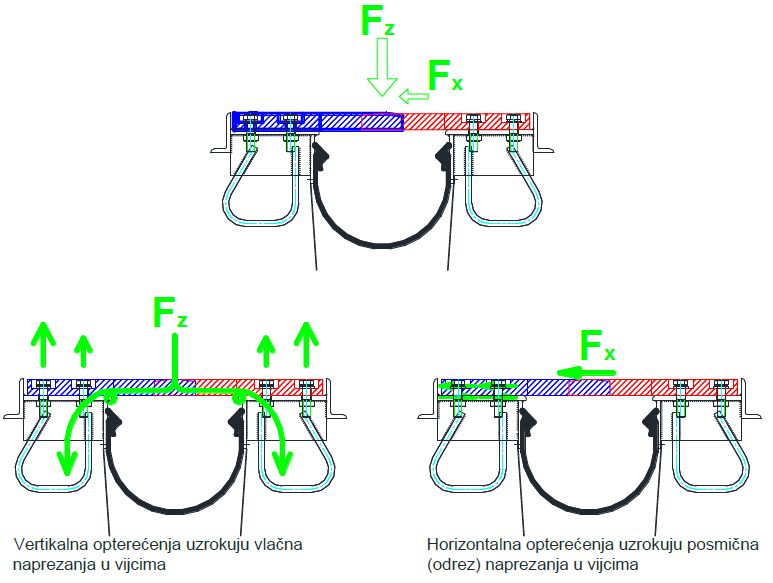

Loads

VVehicle while crossing through the device transmitted vertical and horizontal load PF module connected to the elements of the substructure expansion joints.

Due to "comb" the surface of transitional devices, transition comfort is excellent. Steel surface device is divided into small longitudinal fingers, which at its top with a chamfer, which aims to mitigate the potential impacts of a finger expansion joints so that they do not cause impact on rubber-wheeled vehicles.

To prevent the passage of dirt, water and corrosive liquids through the device, POLIFINGER transitional devices are equipped with textile reinforced rubber gasket (EPDM), which is attached to the subframe devices. The connection is watertight and safe for structural elements under the transitional devices. The gasket can be easily replaced by removing the old seals and drawing new seals. It is not necessary to stop traffic while changing seals.

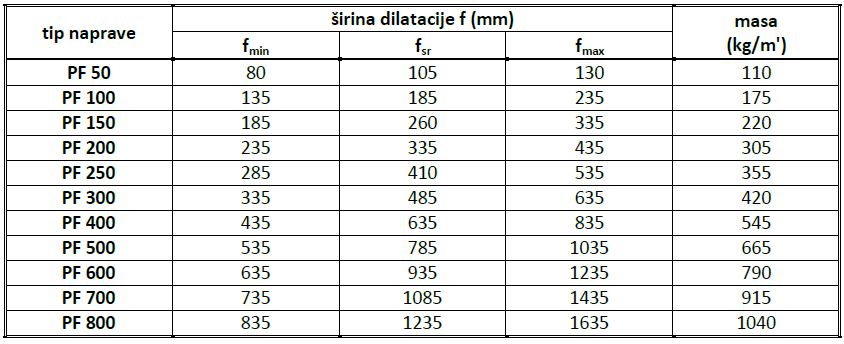

Model series, developments and measures

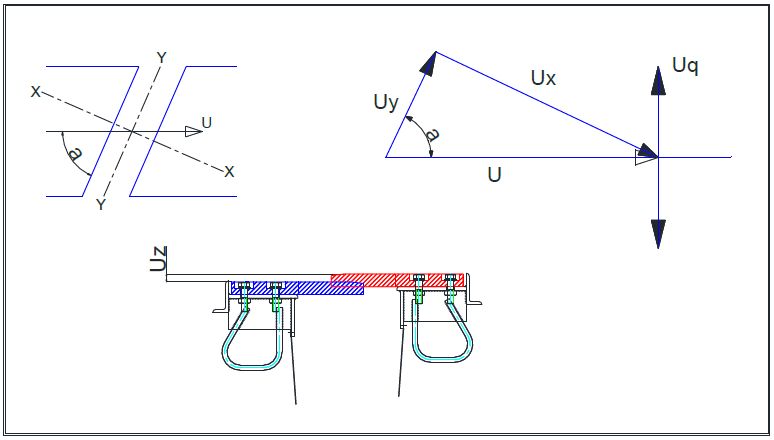

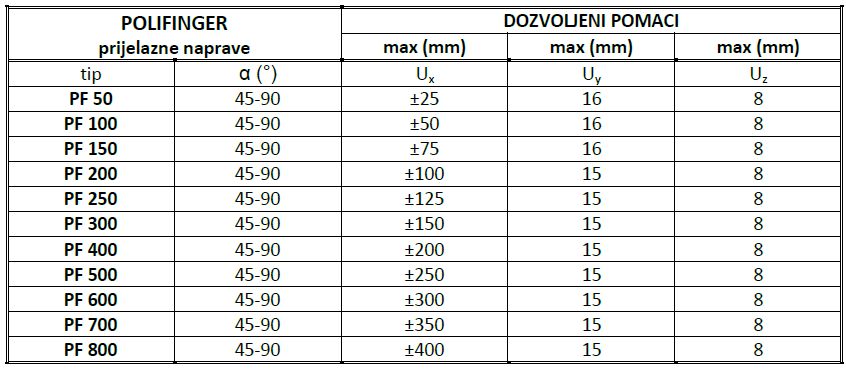

The overall mobility "U" in the main direction (longitudinal axis of the object) is defined by two components of movement Ux and Uy perpendicular and parallel to the axis of the expansion joints.

Type expansion joints choose taking into account the component Ux and a maximum width between slats. To facilitate the design and selection of expansion joints main data are stored in a table.

CATALOGUE - Polifinger

CATALOGUE - Polifinger